|

What's going on here?

Hint: ask yourself why longer levers generate more force Bonus question: from a kinematic chain perspective, what is the bar count of this linkage? Build pictures are here.

0 Comments

Why can Klann's Mechanical Spider handle heavier loads than Strandbeest and TrotBot?

Walkers require very strong frames to handle the weight and torque. This is best accomplished through the use of triangles. Also, linkage attachments to frames need holes at precise locations, which often requires the use of right triangles. However, making right triangles is difficult as LEGO can only use integer numbers to construct them, such as 3,4,5 etc…

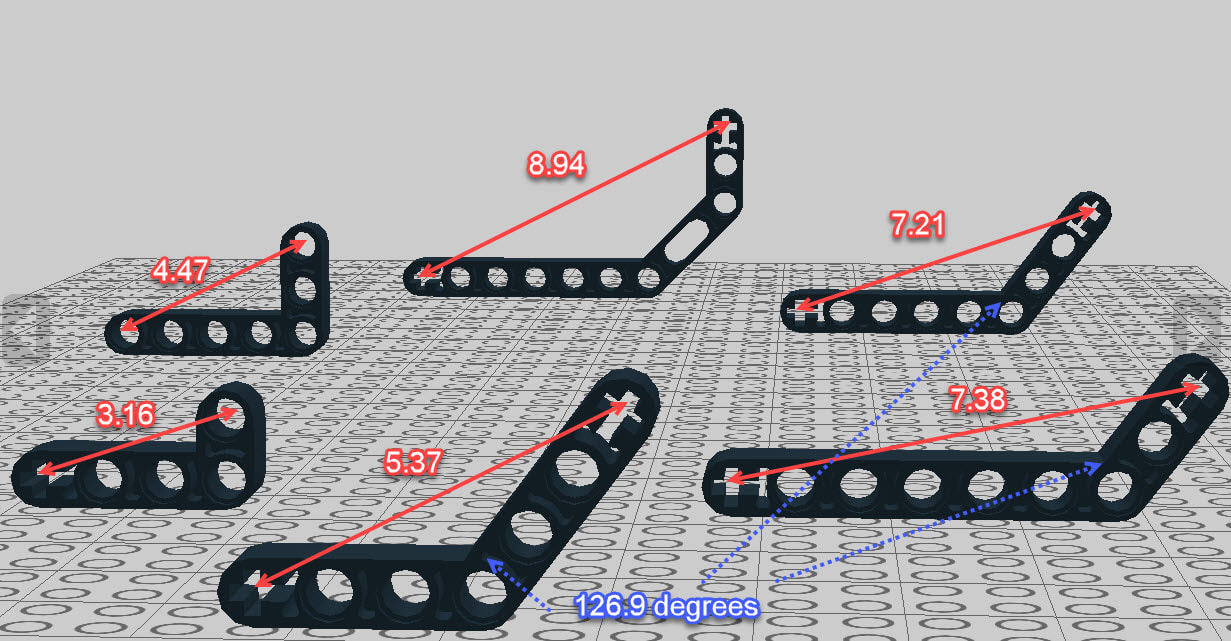

Since the 3,4,5 or 6,8,10 triangles might not work well with a walker frame, what other integer triangles, or almost integer triangles, can you come up with to create a stronger frame? Alternatively, how could we use LEGO's bent lift-arms to create sturdy right triangle-based frames? The parts and their lengths are below. Remember, when counting how long a LEGO beam is, the first hole is always counted as 0! In other words, a beam with 9 holes has a length of 8. If you don't count LEGO beam lengths in this way then you won't be able to use the Pythagorean Theorem or Law of Cosines to solve for which beams to use as diagonal members. |

Categories

All

Archives

February 2023

|

RSS Feed

RSS Feed