|

Posted by Wade

These experiments are a continuation of an earlier post on shock-absorbing feet, where I wasn't able to significantly smooth walker gaits without either:

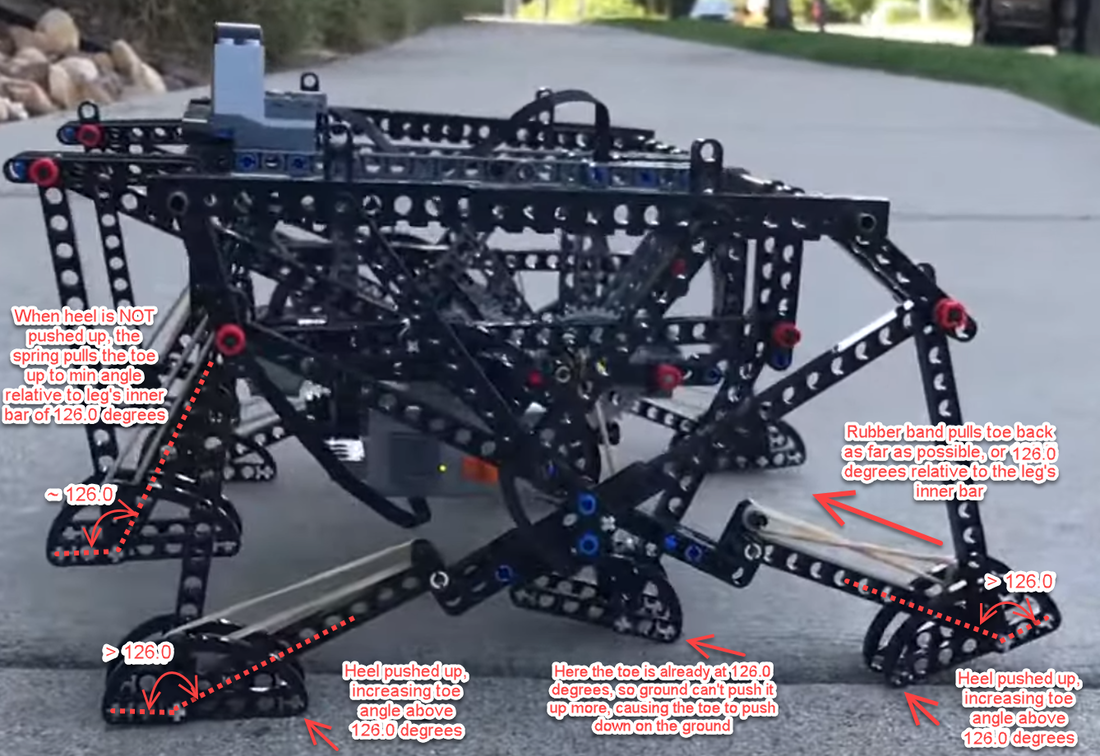

This variation of shock-absorption via spring-loaded ankles avoids these problems, and is able to smooth Strider's gait while also increasing the percentage of foot-contact per crank rotation, which boosts stability and reduces slightly the need for more legs. The need for damping is reduced by using a spring which is weak enough to allow the heel to "bottom out" as the robot steps onto the ground, which mitigates bouncing. Yet, as can be seen in the second video below, the heels' springs still absorb much of the shock when the robot steps down to the ground hard and fast even if the heels are compressed completely. Additionally, much of the energy absorbed by compressing the heel and stretching the spring is returned as the foot is lifted off the ground. Furthermore, the arc of the heel's rotation around the ankle joint tends to push the robot forward when the front foot lands, or the rear foot lifts, which helps to compensate for Strider's slightly slower foot-speed at that point in its foot-path. There are a number of ways this idea could be implemented, such as via a compression spring that pushed the heel down, but I opted to use a simple rubber band to pull Strider's toes up, which rotates the foot at the ankle joint and pushes the heel down.

Strider's toes function as usual here, where they push down on the ground on the inner side of the foot-path. The toes are not involved in the heel's spring-based shock absorption - only the heels absorb shocks.

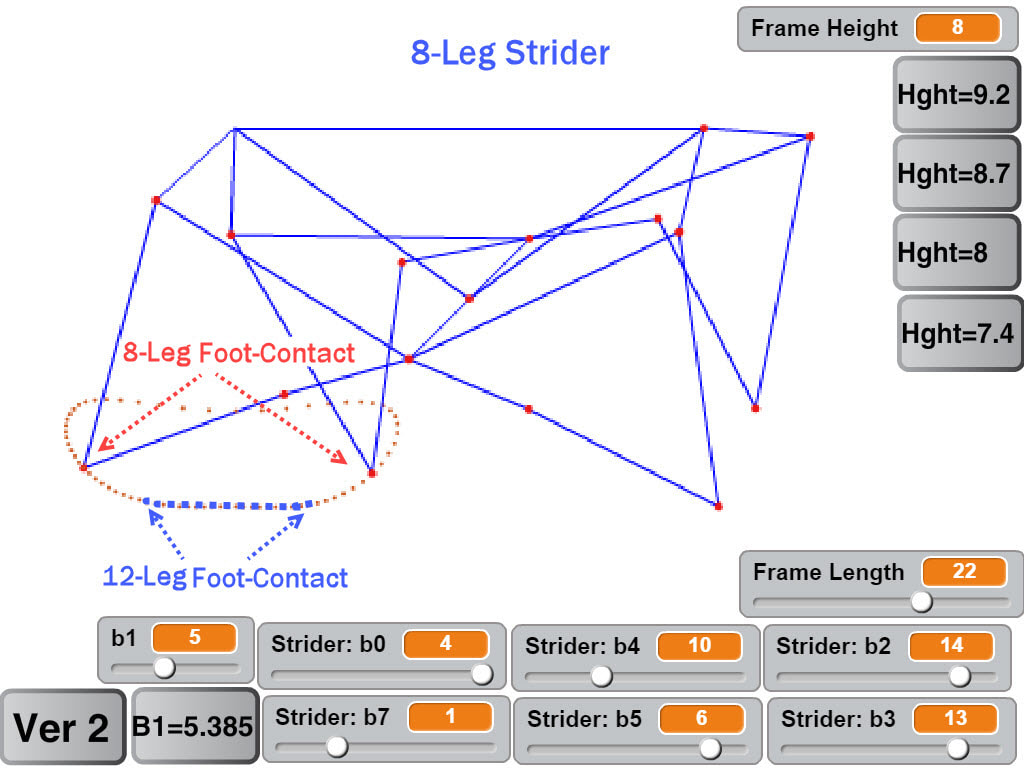

Below are tests of two variations of shock-absorbing heels. The first test uses longer heels like the GIF above: The second test below uses shorter heels, which don't always compress fully and look to be inferior to longer heels....but some load-bearing, top-speed, and high-speed vibration tests should be performed to confirm which heel length is indeed superior. Conclusions? I recommend adding the longer version of shock-absorbing heels to 8 and 12 leg Strider robots, and as their weight increases use stronger rubber bands to handle the weight. However, I do not recommend building huge Striders in 8-leg versions regardless of adding shock-absorbing heels. Strider's high, boat-shaped footpath has a longer perimeter than walkers with triangular foot-paths like Jansen's Strandbeest or Klann's linkages, which reduces Strider's foot-contact with the ground to about 1/3rd of the crank's rotation. Therefore, for large-scale Strider builds use at least 12 legs. Good luck, Wade

2 Comments

Posted by Wade

As we learned during our attempt to scale up TrotBot, not all robot's legs will walk by pushing or pulling the robot. When we pushed TrotBot Ver 0 with its more rectangular-shaped footpath, the cranks would initially rotate, and then the linkage would freeze and the feet would skid on the pavement. Instead, we had to manually rotate TrotBot's cranks to make it walk:

The same thing happened when we tried to push our LEGO Klann walkers with the motors disengaged - the feet would skid and the cranks would not rotate. In both cases, this was due to the linkage being at a sort of reverse Dead-Point.

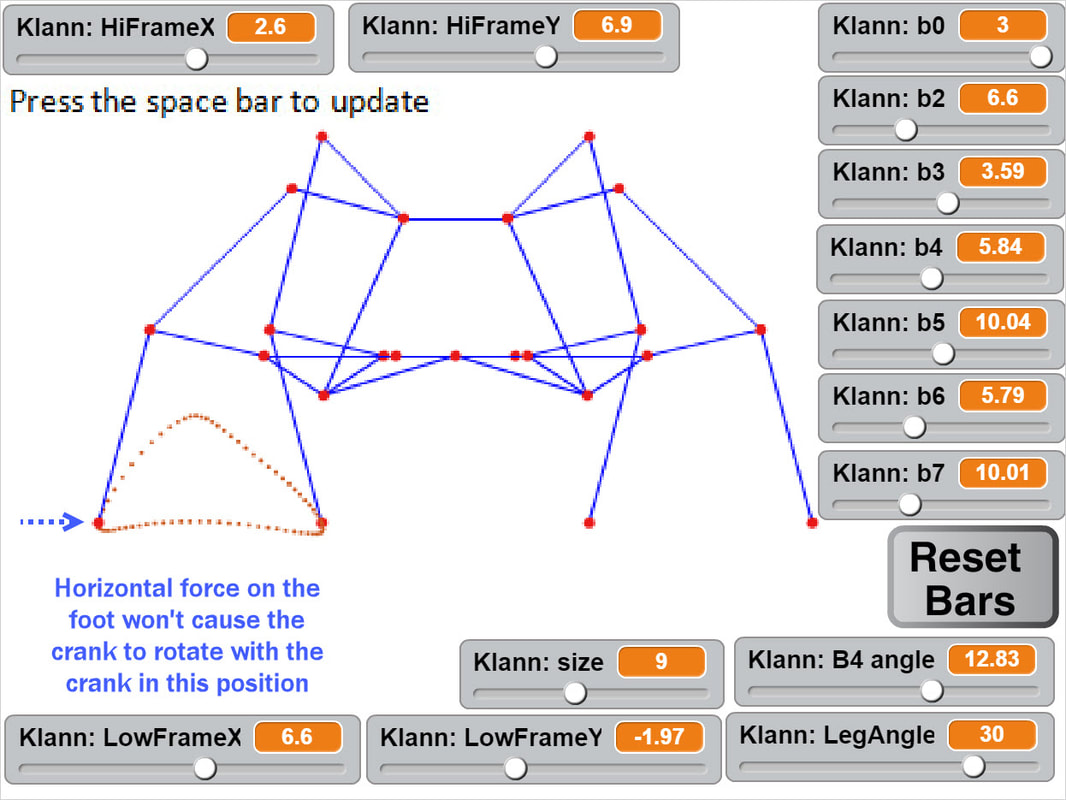

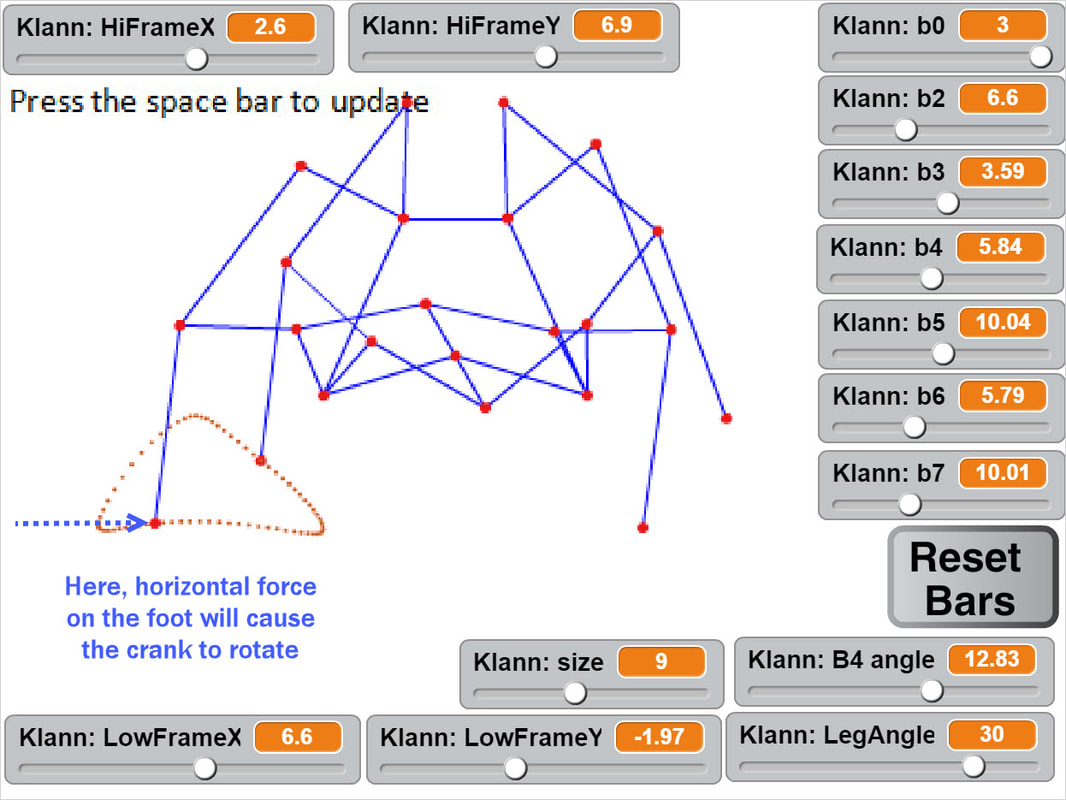

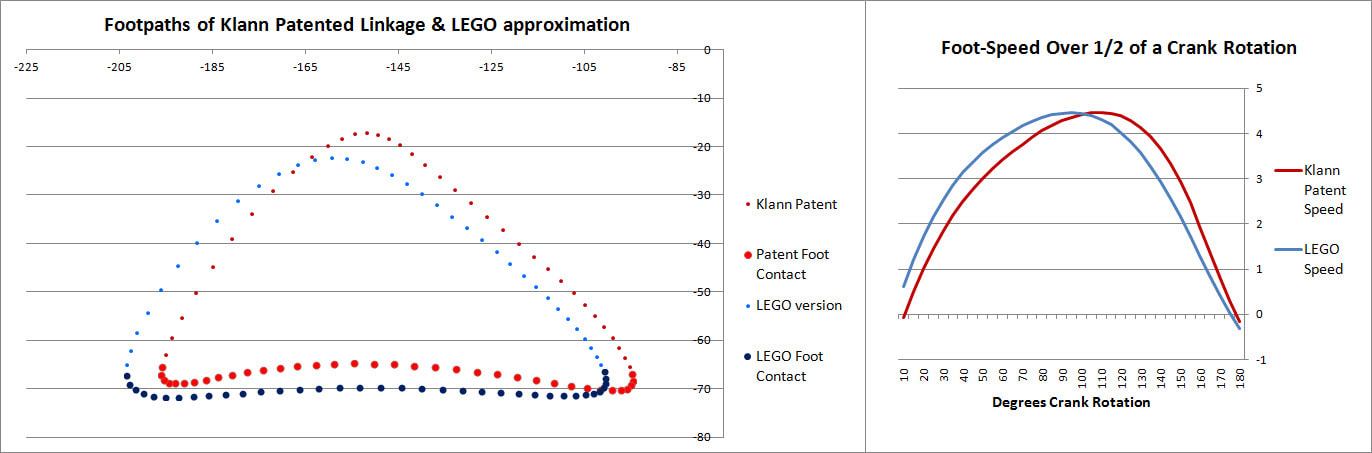

This behavior can be predicted from the image of Klann's linkage below. Notice that when the crank is in such a horizontal position, all four feet are at the bottom corners of Klann's triangular foot-path. Also notice that the feet slow to a virtual stop at these corners, as indicated by how bunched together the red dots are at the bottom corners of the foot-path. In other words, rotating the crank +/- 10 degrees from this horizontal position would barely cause the feet to move. This also means that pushing the robot (and hence the feet) would not cause the feet to move nor the crank to rotate. Instead, it would only cause the legs to bend and the feet to skid, as happens with our prototypes.

This behavior is also indicated by linked bars being parallel - notice in the image above that the legs' connections to the crank are parallel with the crank, a tell-tale sign of a Dead-Point.

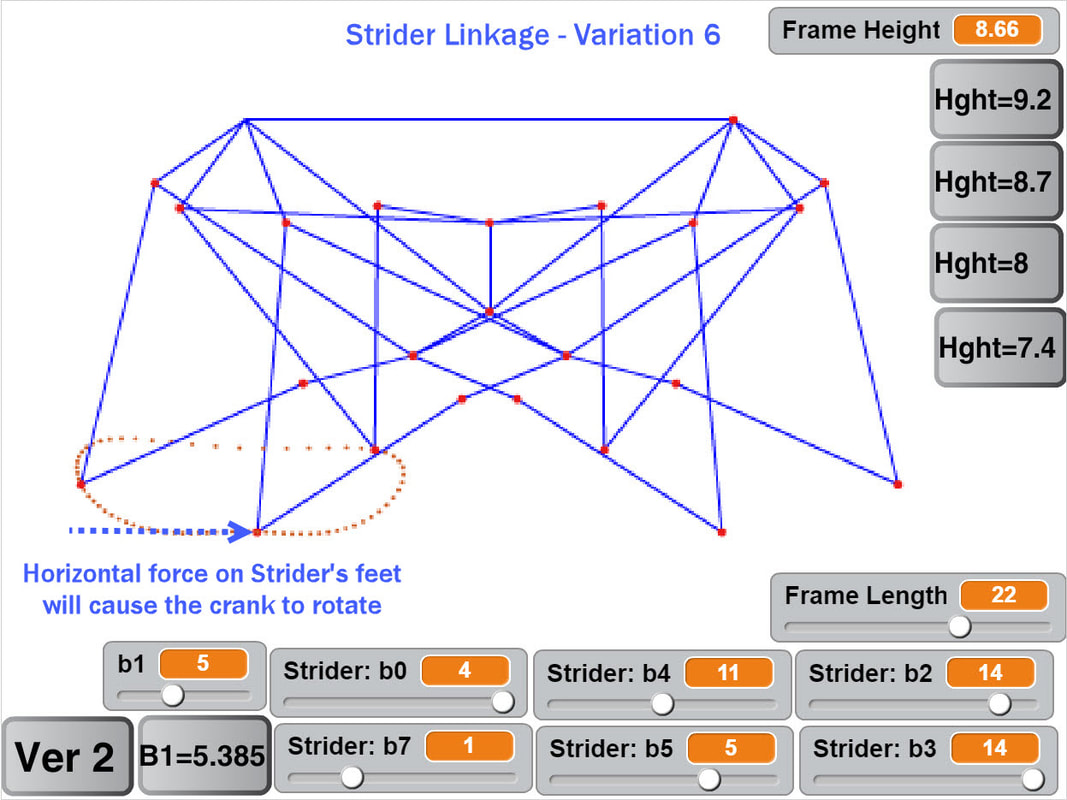

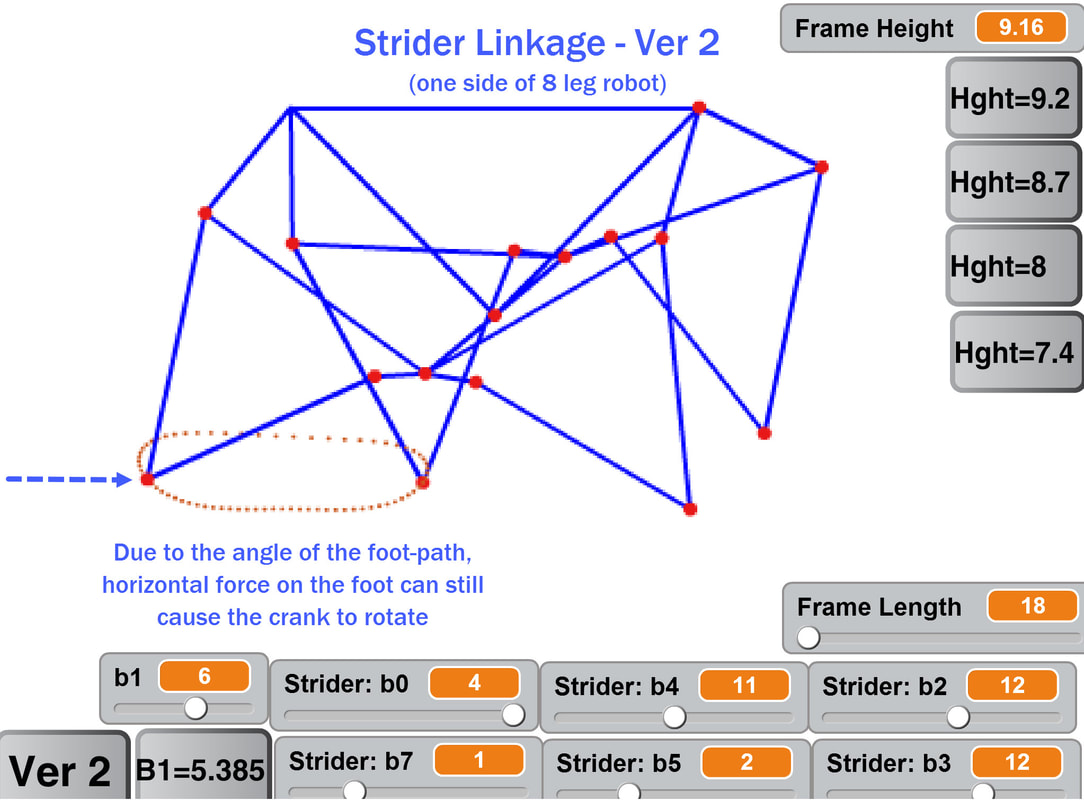

Below the crank has been rotated past this dead point where crank rotation causes foot movement and vice versa: If another pair of legs were added to each side of Klann, as done in the simulation of Strider below, then maybe its legs could be driven by pushing the robot (although one of Klann's feet would still skid at the corner of the foot-path, so it may not work so well - maybe adding feet that could slide or rotate a little would help?) Here's a test to see how easily this linkage variation #6 of Strider's mechanism can be driven by an external force - gravity in this case:

Notice how the robot wavers slightly to the left and right as it descends, due to the foot-speed varying a little. Linkage variation 7 below has more consistent foot speed, and waivers less

Passive walking can also be tested by pulling the robot with a rope: Strider's legs can also be driven by pushing the robot when built in an 8-leg version, although not nearly as efficiently as 12-leg versions, and the ramp's slope had to be increased to get an 8-legged Strider to walk below:

Posted by Wade

Like how we appreciate Nike's when running on concrete, large-scale walkers benefit from shock-absorbing feet. By increasing the spring's travel, shock-absorbing feet may also be able to smooth the gaits of high-stepping walkers like TrotBot and Strider. And of course this would create new problems to be solved! First, here's the Mondo Spider's feet in action, which provide some shock absorption, and they also slide on the smooth concrete, which helps with turning and with smoothing Klann's speed:

It walks amazingly fluidly considering how Klann's foot-path comes to a stop at each end, and the springs probably smooth the transition between feet somewhat:

Watching the video raises some questions, like:

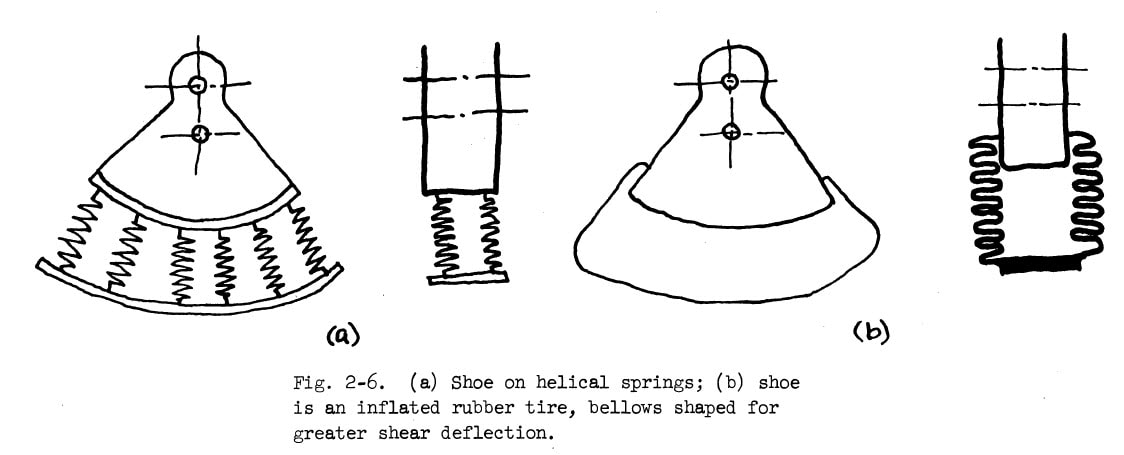

Implementing Klann's linkage without shock-absorbing feet that slide results in a more halting gait, as can be seen in this version of the Walking Beast: Our LEGO Klann walkers could also benefit from shock-absorbing feet when walking on hard surfaces like wood floors: Next, here are some shock-absorbing feet ideas from Mechanical Walker pioneer, Professor Joseph Shigley: Feet with such springs extend the feet toward the ground. So, in addition to absorbing shocks, the springs also increase the percentage of ground contact of each leg per crank rotation. Taken to an extreme, feet with very long springs could theoretically increase an 8-legged Strider's ground-contact to the point that it always had one foot on the ground at each corner of robot, and do so without causing the robot's height to drop when the feet touching the ground switch. This is because both of the feet will be near the ground at the foot transition, meaning two springs will be pushing the robot up, reducing how far the robot falls at foot transitions. However, a few of the (probably numerous) issues of long-spring feet are:

So, springs long enough to convert a large-scale Strider to an 8-legged walker wouldn't be feasible, but shock-absorbing feet can still help to reduce the force of impacts of feet with the ground. To illustrate, below are simulations of adding shock-absorbing feet to 12-leg versions of TrotBot and Strider (assuming perfectly elastic springs without damping that comply with Hook's Law, and ignoring inertia and spring oscillation): Notice how adding springs to TrotBot's feet causes the rear feet to skid slightly as its feet are lifted off the ground (because its foot-speed slows at that point in its foot-path). Strider's linkage simulated below has more consistent foot-speed, so its rear feet do not skid when springs are added As an alternative to springs, foam padding can be added to the feet which also provide some damping. This idea is tested below which explores how much an 8-legged Strider's gait can be smoothed by adding thick foam pads to its feet: Below tests foam "boots" on snow and ice: And thinner, foam weather stripping for doors was used in this feasibility test of a jumping robot: On a related note, our LEGO walkers' gaits are somewhat smoothed by the flexing of the metal support rods, although such shock-absorption isn't consistent since it varies depending on how far the legs are from the inner frame. You can see this in action in the following video, where the outer frames bounce more than the center frame: |

Categories

All

Archives

February 2023

|

RSS Feed

RSS Feed