|

Posted by Ben

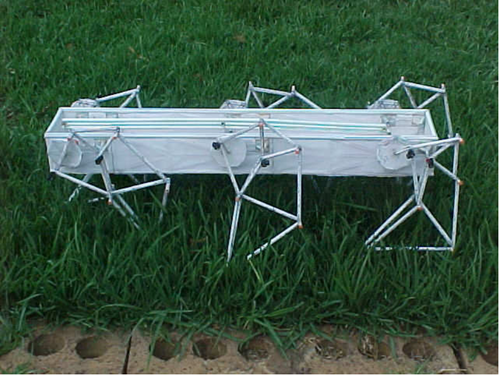

Boris Ingram has been creating some remarkable walkers! Inspired by Theo Jansen’s Strandbeest, Ingram set out to create his own highly functional versions in the early 2000’s. His initial attempt is shown below and was constructed out of plastic straws due to their inexpensiveness and excellent performance under tension and compression forces.

However, like us, Ingram wanted to go bigger. To that end he wrote some linkage simulation software that would allow him to optimize the Strandbeest linkage for:

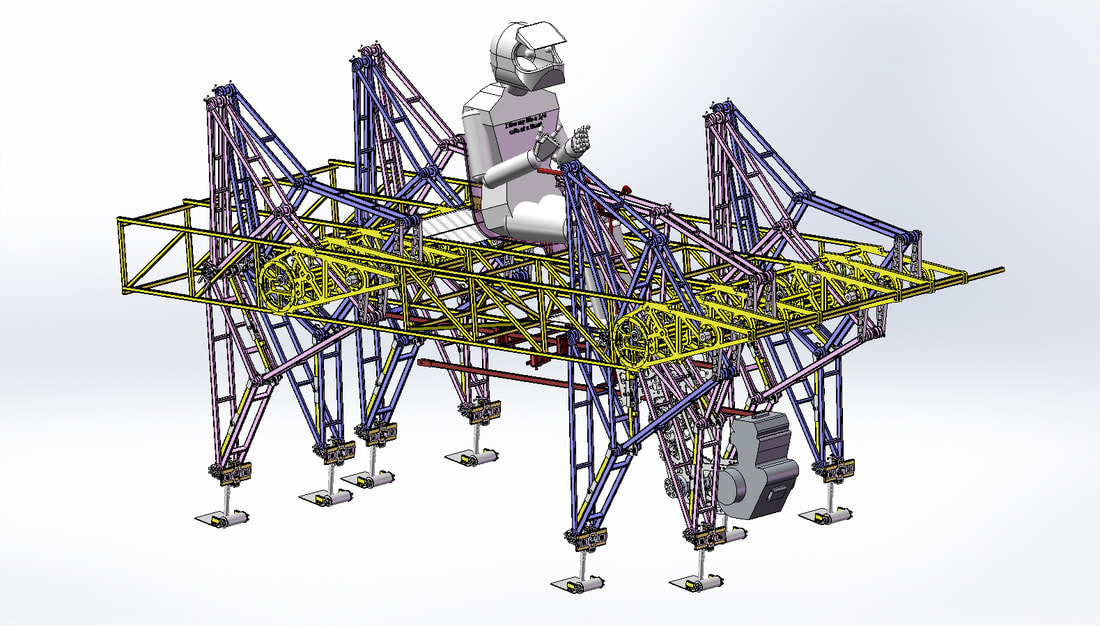

With this new linkage configuration Ingram was able to construct the absolutely insane 6-legged machine below:

After completing this machine and getting a PhD in mechanical engineering, Boris took a 7 year hiatus from building. During that time he began to brainstorm ways to improve upon his already impressive work.

Boris’ latest design is an octopedal walker. He chose to move from 6 to 8 legs because with only 6 legs there were times where an individual leg was taking a disproportionately large amount of the weight of the machine, somewhat compromising its structural stability. The octopedal machine has the following features: 1. Steerable with variable stride lengths. This allows the legs on the inside of a turn to have a shorter stride length and cover less horizontal distance with each crank rotation. This is important because the outer legs need to travel faster to keep up with the inner legs, as you can see in this classic video on how differentials work:

2. Feet with auto reset in case they meet obstacles during foot placement, a key feature for going over complex kinds of rough terrain.

3. A newly optimized set of linkage dimensions which produce a foot-path that is almost totally flat during the walking phase. This allows the machine to walk more smoothly which in turn reduces the force loads on the legs. 4. Non-constant rotational speed on crank which eliminates deviations in longitudinal velocity (foot-speed). 5. Welded steel construction and ball bearings for low friction. The machine weighs in at about 500 kg with a Kawasaki 200ccc motorbike engine. 6. An additional reduction box incorporating reverse gear and ability to drive inner or outer legs for tank like steering 7. And the ability to ride it! The CAD model of it can be seen below:

While Boris has done the lion's share of the work, he could use some help from aspiring engineering interns!

If anyone has any interest in helping Boris in the construction of this machine you can contact him at: [email protected]

0 Comments

Leave a Reply. |

Categories

All

Archives

February 2023

|

RSS Feed

RSS Feed